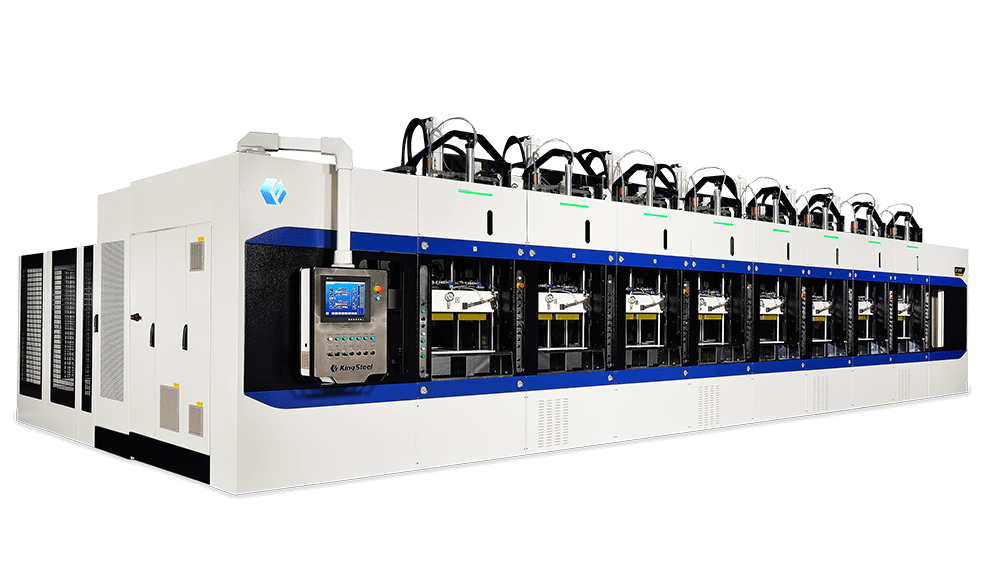

Ethylene Vinyl Acetate (EVA) chemical foaming injection is mainly used for shoe sole production. The addition of rubber or plastic materials produces the Master Batch, which significantly improves the product's durability and temperature resistance. KingSteel leads the EVA chemical foaming injection field with its linear multi-station equipment. In 2007 we developed the dual-color injection forming machine, resulting in the world's first single-injection process that produces a dual-color and dual-hardness product. In 2012 we developed the world's first TwinJet® dual injection (with four sets of injection nozzles) equipment to meet customer needs for mass production and small-quantity sampling.

Four Injectors flexible for dual and single color production Suitable for small, diverse and multi-color orders, which can greatly increase the utilization.

Efficient vacuum system with two-stage vacuum system outside and inside of the mold effectively reduces the product defect rate.

Single color two molds per stations with high productivity and high operating friendliness